2025 Royal Enfield Classic 650 Twin Engine Custom

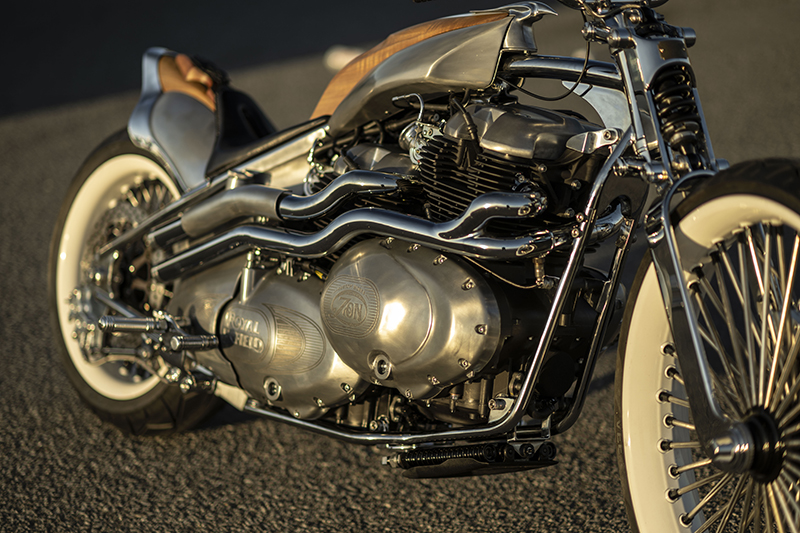

Most custom motorcycles showcased at HCS are powered by large-displacement engines, and the engine’s visual impact is always a crucial element. The CLASSIC 650 engine is beautiful, powerful, and full of character — but for HCS, I wanted to elevate its presence even further. That’s how I arrived at the idea of mounting two engines.

Initially, I imagined a land-speed racer like those competing at Bonneville — two engines aligned inline front and rear, placed in parallel. But that layout made the bike excessively long and large overall. I needed a better solution. Then I thought: what if I offset the height of the two engines.

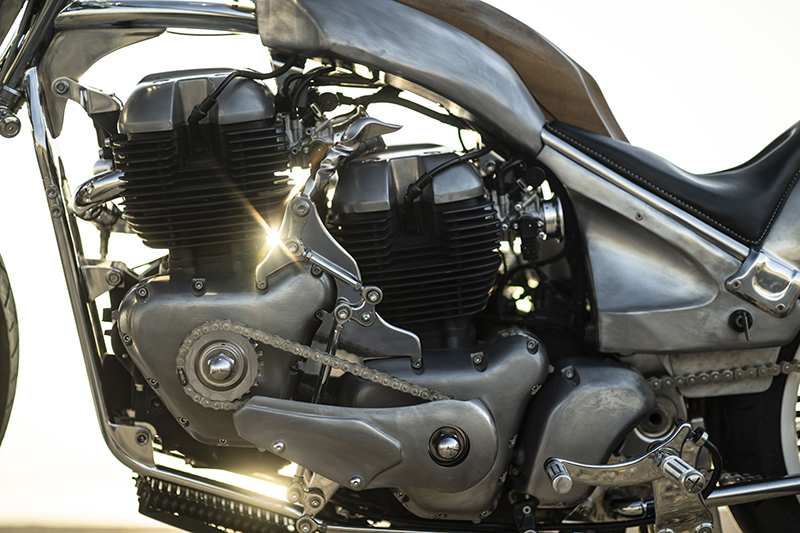

The front engine does not require a gearbox, so by separating the transmission section and trimming the crankcase, I could position it closer to the rear engine, which retains the gearbox. By staggering their height, I reduced the distance between the two units even more — achieving the powerful presence of a dual-engine machine while keeping the overall chassis compact.

I also realized that land-speed racing feels somewhat distant from the mainstream custom motorcycle culture in Japan. Choppers, on the other hand, are extremely popular. Debuting a dual-engine chopper would create a much stronger reaction — and personally, I have always loved choppers. For my first-ever dual-engine build, I strongly wanted to pursue a chopper style.

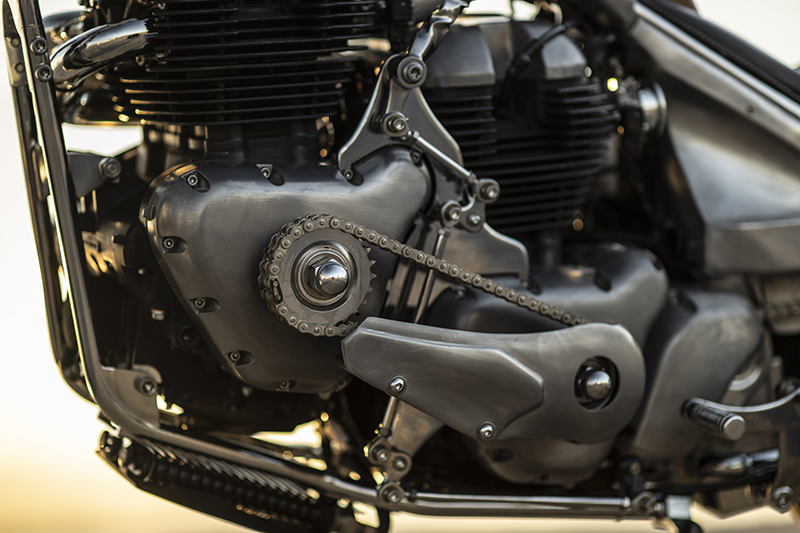

The most challenging task was determining how to mechanically connect the two engines. Fortunately, the left-side magneto cover gives access to the crankshaft. I fabricated an extension shaft and mounted a primary gear there, linking the two engines via a primary chain. It sounds simple when explained now, but reaching that solution required a lot of trial and error. I also discovered that the extension shaft for the front engine must use a left-hand thread, and the rear a right-hand thread. Establishing the correct methods for both took time. The chainline of the two primary gears also had to be perfectly aligned and maintained during engine mounting — which demanded high manufacturing precision when building the engine mounts. To place the engines as close as possible, clearance between the front engine’s EFI throttle body and the rear engine’s exhaust pipe was reduced to the minimum. Positioning that correctly, along with the fabrication of the exhaust system, was another challenge.

Synchronizing the two engines was easier than expected. A single ECU manages both. Thanks to the modern engine platform, achieving synchronization was remarkably straightforward.

The front engine has no gearbox, I shortened its crankcase. I have a lot of experience modifying crankcases and cylinder heads of vintage engines — so this process wasn’t too difficult for me.

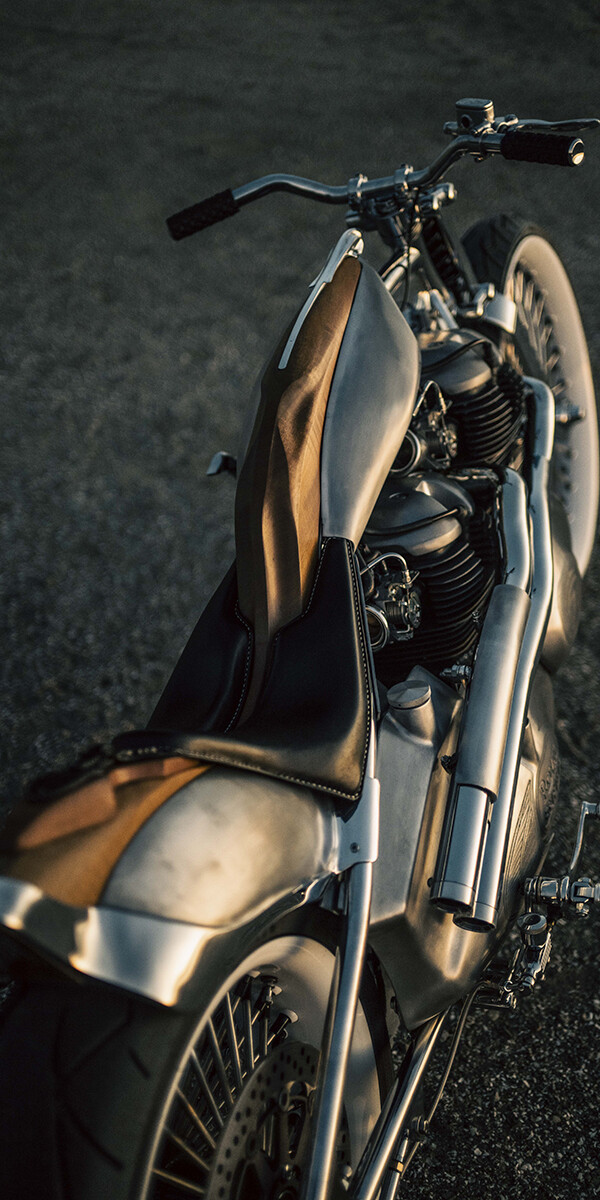

The steel rigid frame and girder fork were originally designed and fabricated in-house. The girder arms were formed using 12 mm steel plates bent, and create a naturally flowing curved surface by hand graving. The top frame tube extending from the steering head is shaped to have both the strength needed to support two engines and the elegance that defines the overall silhouette. To allow engine installation and removal, the lower frame rails are detachable and bolted in place.

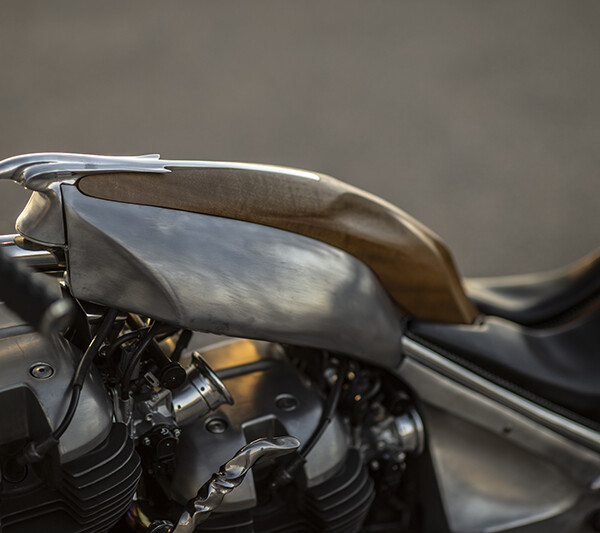

For the exterior elements, I introduced wood — a natural material with its own warmth and power, complementing steel and aluminum. A strip of mahogany, selected with the help of a furniture-craftsman friend, runs along the frame like a backbone, with its grain carefully positioned to show its natural beauty by that friend. To celebrate the raw character of each material — steel, aluminum, and wood — I left all exterior parts unpainted. The jockey shifter is hand-forged Damascus steel. I personally learned forging techniques by visiting a Japanese swordsmith workshop, acquiring a furnace and hammer, and forging the piece myself.

The fuel tank was relocated under the seat on the right side of the bike, handmade by shaping aluminum sheet. The space where the fuel tank would normally be now houses the ECU and electrical components. On the front portion of that fuel tank cover, I placed a bird sculpture carved from a solid block of aluminum. The name “VITA” comes from the Latin word for “life.” Through the bird sculpture, and through the expressive qualities of steel, aluminum, and wood, I wanted to convey a sense of vibrant life and raw energy.

CATEGORIES